Description

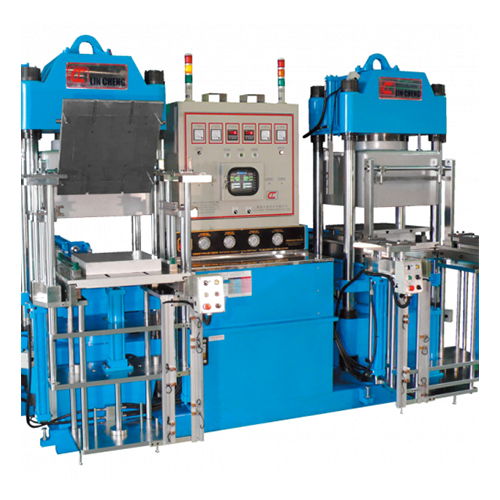

Rubber Molding Machine – High Precision & Durability

Our Rubber Molding Machines are designed for precision production of rubber components, ensuring consistent quality and high productivity. Engineered with robust construction and advanced technology, they are ideal for industries that demand accuracy, repeatability, and efficiency.

Features

-

Heavy-Duty Frame – Built to handle high-pressure molding cycles.

-

Uniform Heating – Ensures consistent curing and reduces defects.

-

Energy-Efficient Design – Optimized hydraulic system lowers power consumption.

-

Easy Operation – User-friendly controls for quick setup and production.

-

Low Maintenance – Precision-engineered parts minimize wear and tear.

⚙️ Applications

-

Automotive Rubber Components (Seals, Bushings, Gaskets)

-

Industrial Rubber Products (Diaphragms, Dampers, O-Rings)

-

Electrical Insulation Parts

-

Household & Consumer Rubber Goods

-

Custom Molded Components